What can we build for you?

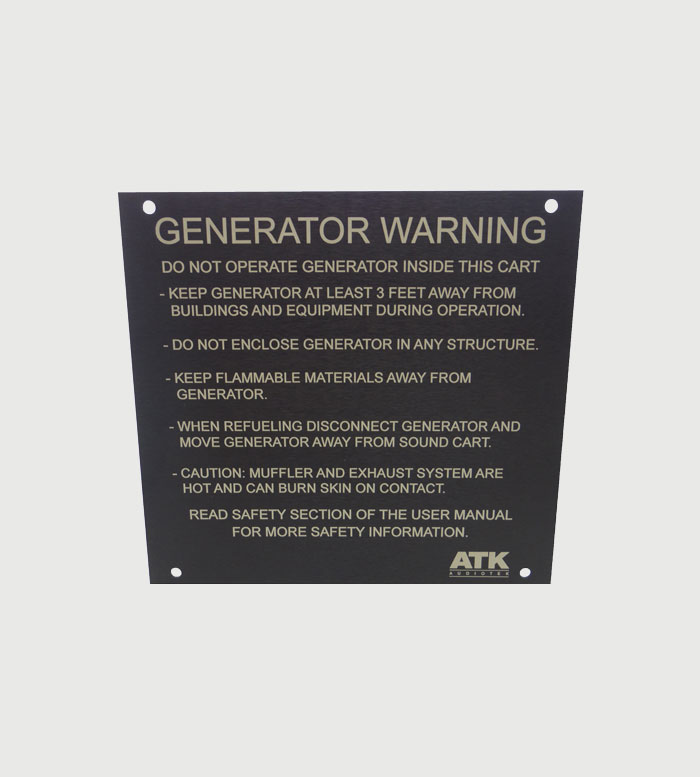

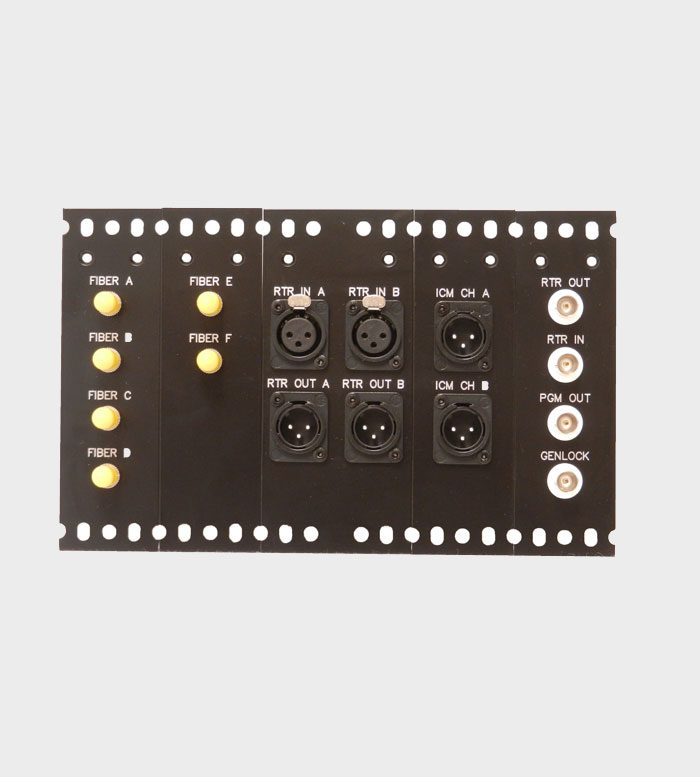

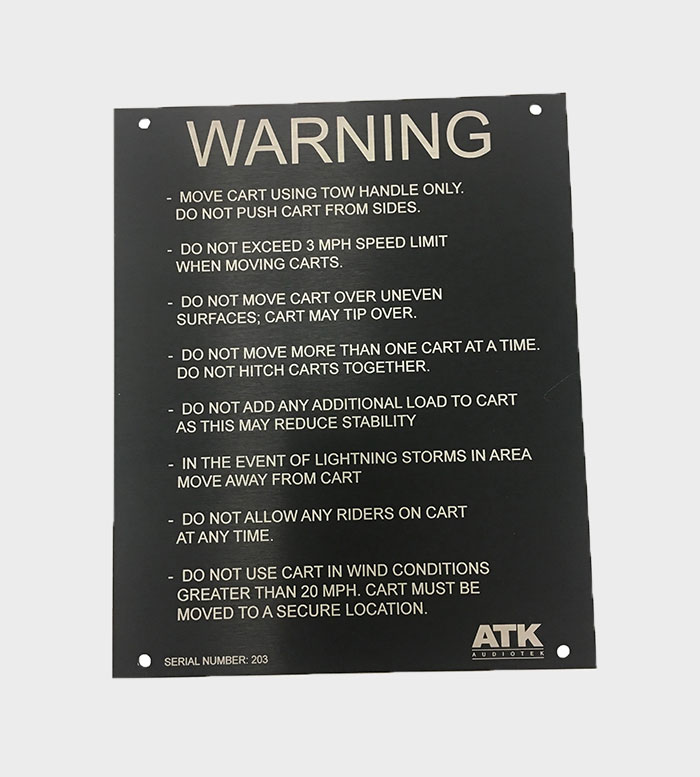

Below are some of the custom panels we have made over the years. Some of these examples are just nice looking custom panels designed to be a reflection of the integrator who installed them, but some involved an engineering collaboration. Great minds, ours and yours, working together to solve a problem or provide benefit to a project.

Let these images inspire you. Let ACE help get it done. Email requirements to: custom@acebackstage.com

Made-to-order custom panels are precision cut and labeled to your exact specifications from a variety of materials. Computer Assisted Drafting (CAD) systems feed data to our rotary CNC machines or laser light cutting systems that define your panel as it is cut. Our unique method of ganged material production results in accurate, fast, and low cost custom panels.

Custom details can be provided by simply emailing manual or computer drawn examples of your requirements. Simple communication from you will allow ACE to quickly facilitate a detailed price quote and computer panel layout for your approval and revision.

Customization details are specific to you and your job, so review the list of options below and let us know what’s important to you. We will work diligently to suggest the best possible solution for your specific requirements, taking all of your circumstances into consideration.

Custom Panels

- PRODUCTION TIME:

- MATERIAL:

- LABELING/ETCHING:

- COLOR ID:

- PANEL FINSIH:

- PREMIUM CONNECTOR

- LOADING WITH SCREWS:

- TAPPED SCREW HOLES:

- RECESSED HATCH FILL:

- CHOICE OF CONNECTORS:

- NO FEE DROP SHIP:

- CAD DRAWING PROVIDED:

- PROJECT PACKAGING:

- PRICING:

Custom Panels

- 2 Weeks

- T6-6061 Aluminum

- Yes

- Available

- Brushed Blk Anodize

- Colored Anodize

- Powder Coat Blk/Wt/Custom

- Available

- Available

- Available

- Available

- Yes

- Yes

- Available

- $$

Custom Panels

- PRODUCTION TIME:

- MATERIAL:

- LABELING/ETCHING:

- COLOR ID:

- PANEL FINSIH:

- PREMIUM CONNECTOR

- LOADING WITH SCREWS:

- TAPPED SCREW HOLES:

- RECESSED HATCH FILL:

- CHOICE OF CONNECTORS:

- NO FEE DROP SHIP:

- CAD DRAWING PROVIDED:

- PROJECT PACKAGING:

- PRICING:

ConnectQuick Panels

- 1 Day

- Acetel Plastic

- Yes

- Available

- Brushed Black

- Included

- N/A

- Included

- Available

- Yes

- Yes

- Available

- $$$

Custom Panels

- PRODUCTION TIME:

- MATERIAL:

- LABELING/ETCHING:

- COLOR ID:

- PANEL FINSIH:

- PREMIUM CONNECTOR

- LOADING WITH SCREWS:

- TAPPED SCREW HOLES:

- RECESSED HATCH FILL:

- CHOICE OF CONNECTORS:

- NO FEE DROP SHIP:

- CAD DRAWING PROVIDED:

- PROJECT PACKAGING:

- PRICING:

CONNECTRIX Panels

- Same Day

- T6-6061 Aluminum

- Available

- Available

- Powder Coat Blk/Wt

- Available

- N/A

- N/A

- Available

- Yes

- Yes

- Available

- $

Remember that custom placement and labeling of connectors in our pre-made CONNECTRIX Panels will always be the best value, providing customization at off-the-shelf pricing. Labeled CONNECTRIX Wall, Rack, or Stage Pocket Panels ship in less than three days from receipt of order.